Running a successful ecommerce business requires a delicate balancing act, and one of the most critical elements is managing your inventory. From ensuring you have enough stock to meet customer demand to minimizing the risk of stockouts and overstocking, inventory management is the cornerstone of any thriving online store. Whether you’re a seasoned entrepreneur or just starting your e-commerce journey, mastering this aspect is paramount to achieving sustainable growth and maximizing profitability.

This comprehensive guide is your ultimate resource for navigating the complexities of ecommerce inventory management. We’ll delve into proven strategies, practical tips, and valuable insights to help you optimize your inventory processes, streamline operations, and ultimately, boost your bottom line. From forecasting demand to implementing effective inventory tracking systems, we’ll equip you with the tools and knowledge necessary to confidently manage your inventory and unlock the full potential of your online business.

What is Ecommerce Inventory Management?

Ecommerce inventory management is the process of overseeing the entire lifecycle of your products, from the moment they are ordered from your suppliers to the point where they are delivered to your customers. This encompasses a wide range of activities, including:

• Forecasting demand: Predicting how much of each product you will need to meet customer orders.

• Ordering from suppliers: Placing orders with your suppliers to replenish your inventory.

• Managing stock levels: Ensuring you have enough stock on hand to meet demand without incurring excessive storage costs.

• Tracking inventory movements: Keeping track of where your inventory is located at all times, from your warehouse to your customers’ doorsteps.

• Optimizing warehouse operations: Efficiently storing and retrieving your inventory to minimize handling time and costs.

• Managing returns and damaged goods: Processing returns and dealing with damaged goods to avoid inventory losses.

Ecommerce inventory management is critical for the success of any online business. By effectively managing your inventory, you can avoid stockouts and delays, improve customer satisfaction, and optimize your profitability.

Why is Ecommerce Inventory Management Important?

In the fast-paced world of e-commerce, efficient inventory management is not just a good practice; it’s a necessity for success. Imagine this: a customer eagerly waits for their online order, only to be disappointed by a message saying “out of stock.” This scenario is a nightmare for any e-commerce business. Not only does it lead to lost sales, but it also damages your brand reputation and customer loyalty.

Effective inventory management goes beyond simply keeping track of your stock levels. It involves a holistic approach to optimizing your supply chain, from forecasting demand to managing storage and fulfilling orders. By having a robust system in place, you can ensure that you have the right products, in the right quantities, at the right time. This means:

- Minimizing stockouts and backorders: Frustrated customers lead to negative reviews and lost sales.

- Reducing storage costs: You’ll avoid tying up capital in excess inventory.

- Optimizing shipping costs: Efficient stock management allows for better planning and reduces the need for rush shipments.

- Improving customer satisfaction: Faster order fulfillment leads to happier customers.

- Gaining a competitive advantage: Businesses that can deliver products quickly and reliably gain a competitive edge in the market.

In essence, effective inventory management is the foundation for a thriving e-commerce business. It’s not just about keeping track of products; it’s about ensuring a smooth and satisfying experience for your customers, maximizing your profits, and ultimately, driving your business towards success.

Challenges of Ecommerce Inventory Management

Managing inventory for an e-commerce business presents unique challenges that go beyond traditional brick-and-mortar stores. These challenges arise from the complex interplay of factors such as fluctuating demand, geographically dispersed customers, and the need for real-time visibility. Let’s delve into some of the key obstacles that e-commerce businesses face when it comes to inventory management.

Forecasting Demand:

Accurately predicting future demand is crucial for maintaining optimal inventory levels. The challenge lies in the dynamic nature of online sales, where factors like seasonal trends, marketing campaigns, and product launches can significantly impact demand. Failing to forecast accurately can lead to overstocking, resulting in wasted capital and storage costs, or understocking, leading to lost sales and customer dissatisfaction.

Managing Multiple Warehouses:

As businesses scale, they often find themselves managing inventory across multiple warehouses to cater to geographically dispersed customers. This necessitates efficient inventory allocation and tracking across different locations, adding complexity to the management process. Coordinating shipments, maintaining accurate inventory counts, and optimizing warehouse utilization become critical for success.

Real-Time Visibility:

E-commerce thrives on speed and efficiency. Customers expect prompt order fulfillment, demanding real-time visibility into inventory availability. The challenge lies in maintaining accurate, up-to-the-minute inventory data across all channels. Delays in updating inventory information can result in lost sales, frustrated customers, and negative reviews.

Managing Returns:

Returns are a significant part of the e-commerce landscape. Unlike physical stores, where returns are handled directly, e-commerce businesses face the challenge of managing returns efficiently from multiple locations. Tracking returned items, processing refunds, and ensuring proper restocking procedures are essential to minimize losses and maintain customer satisfaction.

Optimizing Shipping Costs:

Shipping costs play a crucial role in e-commerce profitability. Optimizing shipping methods, carrier selection, and fulfillment strategies becomes a priority. The challenge lies in finding the balance between cost-effective solutions and providing timely and efficient delivery to meet customer expectations. Balancing these factors can be tricky, as shipping costs can significantly impact profitability.

Key Metrics for Ecommerce Inventory Management

Effective inventory management is crucial for any ecommerce business. By tracking the right metrics, you can optimize stock levels, minimize losses, and maximize profits. Here are some key metrics to monitor:

Inventory Turnover Rate: This metric measures how quickly inventory is sold and replaced. A higher turnover rate indicates efficient inventory management. To calculate it, divide the cost of goods sold by the average inventory value.

Days Sales of Inventory (DSI): This metric shows how many days it takes to sell the current inventory. A lower DSI indicates a faster inventory turnover. To calculate it, divide the average inventory value by the cost of goods sold per day.

Inventory Accuracy: This metric measures the accuracy of your inventory records. A high inventory accuracy rate helps prevent stockouts and overstocking. To calculate it, compare your physical inventory count to your inventory records.

Stock-to-Sales Ratio: This metric shows the ratio of inventory value to sales. A lower ratio indicates efficient inventory management. To calculate it, divide the average inventory value by the total sales for a period.

Order Fulfillment Rate: This metric measures the percentage of orders that are fulfilled on time. A high order fulfillment rate is essential for customer satisfaction. To calculate it, divide the number of orders fulfilled on time by the total number of orders.

Backorder Rate: This metric measures the percentage of orders that are backordered due to insufficient inventory. A low backorder rate helps minimize customer dissatisfaction and lost sales. To calculate it, divide the number of backorders by the total number of orders.

By monitoring these key metrics, you can gain valuable insights into your inventory management performance and identify areas for improvement.

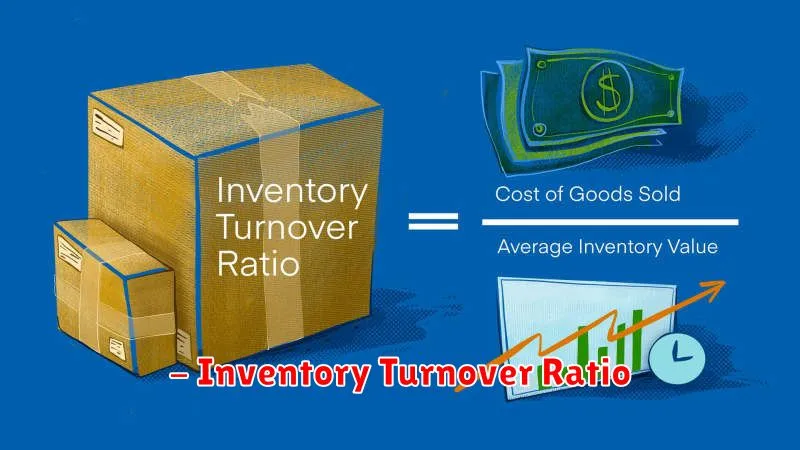

Inventory Turnover Ratio

The inventory turnover ratio is a crucial metric for evaluating the efficiency of your ecommerce inventory management. It measures how quickly you sell and replace your inventory over a specific period. A higher turnover ratio generally indicates efficient inventory management, while a lower ratio may suggest excess inventory or slow-moving products.

To calculate the inventory turnover ratio, you can use the following formula:

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory

Where:

- Cost of Goods Sold (COGS): The direct costs associated with producing or acquiring the goods you sell.

- Average Inventory: The average value of your inventory over a specific period (e.g., month, quarter, year).

For example, if your COGS for the year is $100,000 and your average inventory is $25,000, your inventory turnover ratio would be 4. This means that you are selling and replacing your entire inventory four times a year.

Benefits of Tracking Inventory Turnover Ratio:

- Identifies slow-moving or obsolete products.

- Helps optimize inventory levels and reduce storage costs.

- Provides insights into demand patterns and allows for better forecasting.

- Improves cash flow by reducing tied-up capital in inventory.

Factors that Influence Inventory Turnover Ratio:

- Product demand

- Inventory management practices

- Pricing strategies

- Supply chain efficiency

By monitoring your inventory turnover ratio and analyzing the factors that influence it, you can make informed decisions to optimize your inventory management strategy and achieve greater success in your ecommerce business.

Sell-Through Rate

Understanding your sell-through rate is crucial for effective inventory management. This metric measures the percentage of inventory sold during a specific period, giving you valuable insights into the demand for your products. A higher sell-through rate indicates strong sales and a well-managed inventory, while a lower rate might signal issues with product popularity, pricing, or marketing.

To calculate your sell-through rate, use the following formula:

Sell-Through Rate = (Units Sold / Units in Beginning Inventory) x 100

For example, if you started the month with 100 units of a product and sold 70 units, your sell-through rate would be 70%. This indicates a healthy demand and efficient inventory management.

Here are some tips for improving your sell-through rate:

- Analyze product performance: Track your best-selling and slowest-selling items to understand customer preferences and adjust your inventory accordingly.

- Optimize pricing: Conduct market research and adjust prices strategically to increase demand. Experiment with discounts and promotions to boost sales.

- Enhance product descriptions and visuals: Create compelling product descriptions and high-quality images to entice customers and encourage purchases.

- Improve customer experience: Provide excellent customer service and efficient shipping processes to ensure positive customer interactions and repeat business.

- Leverage marketing strategies: Utilize targeted advertising, social media marketing, and email campaigns to increase product visibility and drive sales.

Days Sales of Inventory

Days Sales of Inventory (DSI) is a crucial metric in e-commerce inventory management. It measures the average number of days it takes to sell your entire inventory. A lower DSI indicates efficient inventory management, while a higher DSI suggests potential issues like overstocking or slow-moving products.

Calculating DSI is straightforward. You divide the average inventory value by the cost of goods sold (COGS) and multiply by the number of days in the period (usually 365 days).

Formula: DSI = (Average Inventory / COGS) * Number of Days in the Period

DSI provides valuable insights for your e-commerce business. By tracking your DSI, you can:

- Identify potential overstocking: High DSI suggests excess inventory, tying up capital and potentially leading to storage and obsolescence costs.

- Optimize inventory levels: Regularly reviewing DSI allows you to adjust stock levels to meet demand accurately.

- Improve cash flow: Efficient inventory management translates to faster sales and improved cash flow, leading to better financial health.

- Assess product popularity: Analyzing DSI for individual products reveals which are selling well and which need adjustments.

By monitoring DSI, you can proactively address inventory challenges and improve your e-commerce operations. Implement effective inventory management practices based on DSI insights to ensure you have the right products in the right quantities at the right time.

Strategies for Effective Ecommerce Inventory Management

Effective inventory management is crucial for any e-commerce business to thrive. It ensures that you have the right products in the right quantities, at the right time, to meet customer demand and minimize potential losses. Implementing a robust inventory management strategy involves carefully considering the following aspects:

1. Accurate Forecasting: Predicting future demand is vital for effective inventory management. Analyzing historical sales data, seasonal trends, and market conditions can help you forecast accurately. Consider using forecasting tools and techniques to improve your predictions.

2. Real-Time Inventory Tracking: Maintaining accurate real-time visibility of inventory levels is essential. Utilize a reliable inventory management system (IMS) that provides real-time updates on stock quantities, locations, and movements.

3. Streamlined Ordering Process: Automate your purchasing process to ensure timely replenishment. Implement a system that automatically generates purchase orders based on pre-defined inventory levels or forecasts.

4. Efficient Warehouse Management: Optimize warehouse operations for smooth inventory flow. Implement proper storage techniques, utilize space effectively, and ensure accurate picking and packing processes to minimize errors and delays.

5. Inventory Control Measures: Implementing strict inventory control measures is crucial to prevent stockouts and overstocking. Use techniques like ABC analysis to prioritize inventory management efforts.

6. Regular Stock Audits: Conduct regular physical stock audits to ensure inventory records match actual stock levels. Identify any discrepancies and rectify them promptly to maintain inventory accuracy.

7. Supplier Management: Build strong relationships with reliable suppliers who can provide consistent quality and timely deliveries. Collaborate with suppliers to optimize supply chains and reduce lead times.

8. Data Analysis and Reporting: Leverage data insights to improve inventory management decisions. Regularly analyze inventory data to identify trends, bottlenecks, and areas for improvement.

By adopting these strategies, you can ensure effective inventory management and contribute to the success of your e-commerce business. It’s important to continually assess and adapt your approach based on changing market conditions and business goals.

Demand Forecasting

Accurate demand forecasting is the cornerstone of successful ecommerce inventory management. It helps you predict future sales, optimize stock levels, and minimize costly overstocking or stockouts.

Here are some key strategies for effective demand forecasting:

- Historical Data Analysis: Leverage past sales data to identify patterns, seasonality, and trends. Tools like moving averages and exponential smoothing can help analyze this data.

- Market Research: Stay informed about industry trends, competitor activity, and consumer behavior to anticipate future demand shifts.

- Sales Forecasts: Collaborate with your sales team to get their insights on upcoming promotions, product launches, and expected sales figures.

- Seasonal Adjustments: Account for seasonal fluctuations in demand by analyzing historical sales data and incorporating relevant external factors.

- Machine Learning: Advanced algorithms can analyze vast datasets, identify complex patterns, and provide more accurate demand predictions.

By implementing these strategies, you can gain a deeper understanding of your customer demand and make informed decisions about your inventory levels, ensuring a smooth and profitable ecommerce operation.

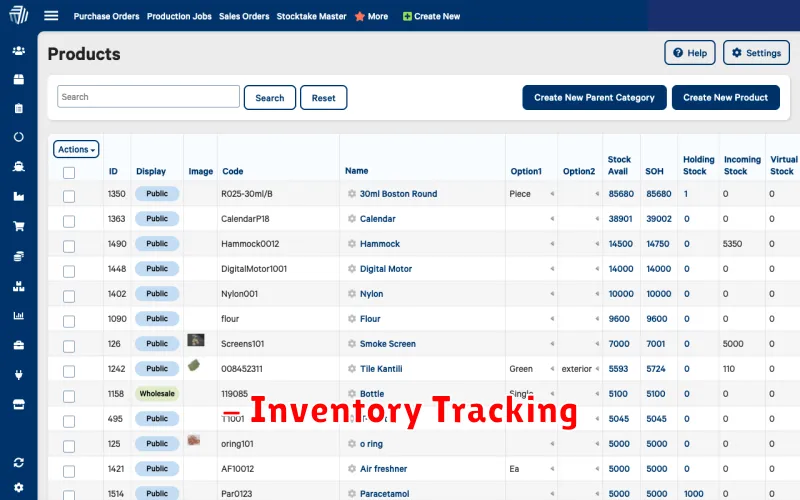

– Inventory Tracking

Accurate inventory tracking is the backbone of any successful e-commerce business. It provides crucial insights into your stock levels, allowing you to avoid stockouts, minimize overstocking, and optimize your supply chain. This, in turn, helps you improve customer satisfaction, reduce fulfillment costs, and maximize profitability.

Here are some essential aspects of effective inventory tracking:

- Real-Time Visibility: Having real-time access to your inventory levels is essential. This allows you to track movement, identify potential issues, and make informed decisions quickly.

- Automated Tracking: Integrate your inventory system with your sales channels and warehouse management software. This automates tracking processes, reducing manual errors and saving valuable time.

- Accurate Data Entry: Ensuring data accuracy is paramount. Mistakes can lead to inaccurate stock levels, causing delays and customer dissatisfaction.

- Regular Audits: Conduct regular physical inventory audits to reconcile your system data with actual stock levels. This helps identify discrepancies and improve accuracy.

- Inventory Management Software: Invest in a reliable inventory management system that provides comprehensive tracking features, reporting capabilities, and integration with other business systems.

By implementing robust inventory tracking practices, you can gain a competitive advantage in the e-commerce world, ensuring smooth operations, efficient fulfillment, and delighted customers.

Warehouse Management

Effective warehouse management is crucial for any successful ecommerce business. It encompasses all aspects of managing your inventory, from receiving and storing goods to picking, packing, and shipping orders. A well-organized warehouse ensures your products are readily available to meet customer demand, minimizing delays and maximizing customer satisfaction.

Here are some key strategies for efficient warehouse management:

- Optimize warehouse layout: Design your warehouse to facilitate efficient workflows. Strategically place storage areas, picking stations, and packing zones for easy access and movement.

- Implement a robust inventory management system: Choose a system that provides real-time visibility into your inventory levels, tracking stock movements, and generating accurate reports. This helps avoid stockouts and overstocking.

- Embrace automation: Utilize technology like automated guided vehicles (AGVs) and warehouse management systems (WMS) to streamline operations, improve accuracy, and enhance productivity.

- Implement proper picking and packing strategies: Optimize picking routes and implement efficient packing procedures to minimize errors and ensure timely order fulfillment.

- Maintain a clean and safe environment: A well-maintained warehouse ensures a safe working environment for staff and promotes efficiency by minimizing clutter and potential hazards.

By implementing these strategies, you can create a smooth and efficient warehouse operation that supports your ecommerce growth and customer satisfaction.

Order Fulfillment Optimization

Order fulfillment optimization is the process of streamlining your order fulfillment process to ensure that orders are processed, packed, and shipped quickly and efficiently. This is a critical aspect of ecommerce success, as it directly impacts customer satisfaction, repeat business, and profitability. By optimizing your order fulfillment, you can reduce shipping costs, minimize errors, and improve overall customer experience.

Here are some key strategies for order fulfillment optimization:

- Choose the right fulfillment model: Consider your business needs, order volume, and budget when selecting a fulfillment model. Options include in-house fulfillment, third-party logistics (3PL), and dropshipping. Each model has its own advantages and disadvantages, so it’s essential to evaluate them carefully.

- Optimize your warehouse layout: A well-organized warehouse can significantly improve order fulfillment efficiency. Ensure that frequently ordered items are easily accessible, and implement a system for tracking inventory levels.

- Invest in automation: Automating tasks like order picking, packing, and shipping can save time and reduce errors. This can be achieved through the use of warehouse management systems (WMS), conveyor belts, robots, and other technologies.

- Offer multiple shipping options: Provide customers with a variety of shipping options, including standard, expedited, and overnight delivery. This allows them to choose the option that best suits their needs and budget.

- Track your metrics: Regularly track your order fulfillment metrics, such as order processing time, shipping time, and customer satisfaction. This data can help you identify areas for improvement and optimize your fulfillment process.

By implementing these strategies, you can significantly improve your order fulfillment efficiency, reduce costs, and enhance customer satisfaction. A well-optimized fulfillment process is essential for any successful ecommerce business.

Safety Stock Management

Safety stock is the extra inventory you keep on hand to prevent stockouts. This can be a buffer against unexpected demand spikes or delays in your supply chain. Managing safety stock effectively is crucial for ecommerce businesses. Here’s how:

Calculate Your Safety Stock: There are various formulas to calculate safety stock. One commonly used approach involves considering lead time, demand variability, and service level. Lead time is the time it takes to receive new inventory. Demand variability refers to the fluctuations in customer demand. Service level represents the percentage of time you want to avoid stockouts.

Factors to Consider:

- Seasonality: Adjust your safety stock based on peak seasons and periods of lower demand.

- Product Value: More expensive products might warrant a higher safety stock to minimize potential losses.

- Supplier Reliability: If a supplier is known for delays, you might need a larger safety stock.

Optimization Strategies:

- Inventory Management Software: Leverage software tools to automate calculations, track inventory levels, and generate alerts for potential stockouts.

- Regular Review: Periodically reassess your safety stock based on current data and market trends.

- Supplier Relationships: Build strong relationships with reliable suppliers to ensure timely deliveries and consistent quality.

By implementing a well-structured safety stock management strategy, you can effectively mitigate stockouts, enhance customer satisfaction, and optimize your inventory costs.

Returns Management

Returns management is a critical aspect of any successful e-commerce business. It’s not just about processing returns, but also about minimizing their impact on your profitability and customer satisfaction. Efficient returns management can be a powerful tool for customer retention and building brand loyalty.

Here are some key strategies to manage returns effectively:

- Streamlined Returns Process: Make it easy for customers to return items. Offer clear return policies, multiple return options (online, in-store, etc.), and pre-paid return shipping labels.

- Proactive Return Prevention: High-quality product descriptions, accurate sizing charts, and detailed product images can help prevent returns by managing customer expectations.

- Excellent Customer Service: Responsive and helpful customer service can resolve issues before they escalate into returns. Be proactive in reaching out to customers with potential return issues.

- Data-Driven Insights: Analyze return data to identify trends and common reasons for returns. Use this information to improve product quality, product descriptions, and your overall returns process.

- Reverse Logistics Optimization: Efficiently manage the reverse logistics process, including receiving, inspecting, and repackaging returned items. Partner with a reliable logistics provider for streamlined returns handling.

- Restock and Repurposing: Consider strategies for restocking returned items. Implement procedures for inspecting returned items and determine if they can be resold, refurbished, or disposed of responsibly.

By implementing these strategies, you can create a smooth and positive returns experience for your customers, minimize your return rate, and protect your bottom line.

Tools and Software for Ecommerce Inventory Management

Effective inventory management is crucial for any successful e-commerce business. To streamline your inventory processes and ensure optimal stock levels, a range of powerful tools and software solutions are available. These tools provide valuable insights, automate tasks, and ultimately contribute to a more efficient and profitable operation.

Inventory Management Systems (IMS): These comprehensive platforms offer a centralized hub for managing your inventory. They track stock levels, monitor incoming and outgoing shipments, generate purchase orders, and provide real-time insights into stock performance. Popular IMS options include:

- Shopify: A popular e-commerce platform with built-in inventory management features.

- Amazon Seller Central: For those selling on Amazon, this platform offers robust inventory management tools.

- NetSuite: A comprehensive suite of business applications, including inventory management.

- Brightpearl: Designed for omnichannel retailers, Brightpearl offers integrated inventory management.

Warehouse Management Systems (WMS): If you operate a physical warehouse, a WMS is essential for managing your storage and fulfillment operations. WMS solutions streamline picking, packing, and shipping, optimize space utilization, and provide visibility into inventory movement within your warehouse.

- Manhattan Associates: A leading WMS provider for large-scale warehouse operations.

- Oracle Warehouse Management: Part of Oracle’s broader enterprise resource planning (ERP) suite.

- Blue Yonder: Focuses on supply chain optimization and includes warehouse management capabilities.

Point of Sale (POS) Systems: For businesses with physical storefronts, a POS system integrates with your inventory management to track sales and update stock levels in real time. Popular POS systems include:

- Square: A versatile POS system with inventory management features.

- Lightspeed: Designed for retail and restaurant businesses, with robust inventory tracking.

- Toast: Primarily focused on restaurants, but offers inventory management capabilities.

Inventory Forecasting Software: Accurately predicting future demand is crucial for avoiding stockouts and minimizing excess inventory. Inventory forecasting software leverages historical data and machine learning to generate accurate forecasts. Popular options include:

- DemandCaster: Provides advanced demand forecasting and inventory optimization tools.

- e2open: Offers a suite of supply chain solutions, including demand planning and forecasting.

- Salesforce Einstein: Leveraging AI, Einstein can forecast demand and provide insights into inventory management.

By utilizing the right tools and software, e-commerce businesses can gain a competitive edge by ensuring efficient inventory management, minimizing stockouts, and optimizing their operations for profitability.

Best Practices for Streamlining Your Inventory Management Process

Streamlining your inventory management process is crucial for success in the competitive world of e-commerce. It ensures you have the right products available at the right time, minimizing stockouts and maximizing sales. Here are some best practices to optimize your inventory management:

1. Implement a Robust Inventory Management System (IMS): A good IMS is the backbone of efficient inventory management. It provides real-time visibility into stock levels, facilitates accurate forecasting, and automates order fulfillment.

2. Optimize Inventory Forecasting: Accurate forecasting is essential for avoiding stockouts or overstocking. Utilize historical data, seasonal trends, and market insights to project future demand and ensure you have the right inventory levels.

3. Implement ABC Inventory Analysis: This method categorizes inventory based on its value and sales velocity. Focus on managing A items (high value, high volume) closely, B items (medium value, medium volume) moderately, and C items (low value, low volume) less frequently.

4. Embrace Automation: Automate tasks such as order processing, stock updates, and warehouse management. This frees up your team to focus on more strategic activities, improves efficiency, and reduces errors.

5. Optimize Your Warehouse Space: Proper warehouse organization is key. Implement efficient storage methods, like bin locations and labeling systems, to ensure easy access and minimize wasted space.

6. Monitor Inventory Turnover: Regularly track inventory turnover rate to gauge how effectively your inventory is being used. A high turnover rate indicates efficient inventory management, while a low rate might signal overstocking or slow-moving items.

7. Establish a Clear Return Policy: A well-defined return policy is essential for maintaining inventory accuracy. Track returned goods, identify issues with products, and use this information to improve future inventory decisions.

By implementing these best practices, you can streamline your inventory management process, reduce costs, improve efficiency, and ultimately drive greater success for your e-commerce business.