Are you running an e-commerce business and struggling to keep up with inventory management? It’s a common challenge, but one that can be overcome with the right strategies. In today’s competitive marketplace, efficient inventory management is not just a good idea, it’s essential for maximizing profits and ensuring customer satisfaction.

When your inventory management is on point, you’ll experience a smoother operation, reduced costs, and ultimately, increased sales. This article will guide you through the best practices for effectively managing your e-commerce inventory, from accurate forecasting to optimizing your warehouse operations.

Understanding Your Inventory Needs

Before you dive into any inventory management strategy, you need to understand your specific needs. It’s not a one-size-fits-all approach. Consider these key factors:

Product Demand: How frequently do your products sell? Understanding your sales history and predicting future trends is crucial. Are you selling a fast-moving product that requires constant replenishment or a slow-moving product where you can afford to have more stock on hand? This will influence your ordering and storage strategies.

Lead Time: How long does it take to receive new stock once you place an order with your supplier? A shorter lead time allows for greater flexibility, but a longer lead time necessitates a more proactive inventory management approach. Be sure to consider this factor when determining your reorder points and safety stock.

Storage Capacity: What is your available storage space? This is especially important for businesses with physical stores or large warehouses. You need to ensure you have enough space to accommodate your current inventory and any future growth.

Product Type: The nature of your products also plays a role. Are they perishable, fragile, or require special handling? This will influence your storage conditions, potential damage risks, and overall inventory management strategy.

Financial Resources: Inventory represents a significant financial investment. How much capital do you have available for purchasing and storing inventory? It’s crucial to balance your need for stock with your financial resources. This might lead you to explore solutions like dropshipping or using a third-party logistics provider.

Implementing an Inventory Management System

An inventory management system is a crucial component of any successful ecommerce business. It helps you track your inventory levels, manage orders, and ensure that you have the right products in stock at the right time. By implementing an efficient inventory management system, you can streamline your operations, reduce costs, and ultimately increase your profits.

There are a variety of inventory management systems available, ranging from simple spreadsheets to sophisticated software solutions. The best system for your business will depend on your specific needs and budget. When choosing an inventory management system, consider factors such as:

- Scalability: The system should be able to grow with your business.

- Integration: It should integrate with your other business systems, such as your ecommerce platform and accounting software.

- Features: The system should offer the features you need, such as order tracking, inventory forecasting, and reporting.

- Cost: Consider the cost of the system, as well as the ongoing costs of maintenance and support.

Once you’ve chosen an inventory management system, you need to implement it properly. This includes setting up your inventory, defining your workflows, and training your staff. It’s also important to regularly review and adjust your system to ensure that it’s meeting your needs. By implementing and maintaining an efficient inventory management system, you can take control of your inventory, reduce waste, and maximize your profits.

Choosing the Right Inventory Management Software

Choosing the right inventory management software (IMS) is crucial for efficient ecommerce operations. A robust IMS can streamline your inventory processes, minimize errors, and ultimately boost your profits. But with so many options available, how do you choose the best one for your business?

Here are some key factors to consider:

- Scalability: Can the software handle your current inventory volume and projected growth?

- Features: Does it offer the features you need, such as order fulfillment, warehouse management, reporting, and integrations with other platforms?

- Ease of Use: Is the interface intuitive and user-friendly for your team?

- Cost: What is the pricing structure and are there any hidden fees?

- Customer Support: Does the vendor offer reliable and responsive support?

Once you have a clear understanding of your needs, you can start researching different IMS providers. Look for software that is:

- Cloud-based: This allows you to access your inventory data from anywhere and makes it easier to scale.

- Integrated with your other ecommerce tools: This can simplify your workflow and reduce the risk of errors.

- Designed for your industry: There are specialized IMS solutions for specific industries, such as retail, manufacturing, and distribution.

Don’t hesitate to request demos from several vendors and compare their features, pricing, and customer support. By carefully choosing the right IMS, you can optimize your inventory management processes, reduce costs, and improve customer satisfaction.

Setting Up Inventory Tracking and Control Measures

To ensure smooth operations and avoid stockouts or overstocking, implementing robust inventory tracking and control measures is crucial. This involves keeping a detailed record of every item in your inventory, from its arrival to its sale. By accurately tracking inventory, you gain valuable insights into product performance, identify potential shortages, and make informed decisions regarding purchasing and restocking.

Several effective techniques can be employed for inventory tracking:

- Barcode scanning: This method uses barcodes to identify and track individual items, automating the process of data entry and reducing errors. Barcode scanners are commonly used in warehouses and fulfillment centers, offering high accuracy and speed.

- Radio Frequency Identification (RFID): Similar to barcode scanning, RFID utilizes radio waves to identify and track tagged items. RFID tags can be attached to products and read from a distance, eliminating the need for line-of-sight scanning. This technology is particularly beneficial for tracking large quantities of items or those with rapid movement.

- Point-of-Sale (POS) Systems: POS systems are integrated with inventory management software, automatically updating inventory levels whenever a sale is made. This real-time data allows for accurate tracking of product availability and facilitates informed decision-making.

- Inventory Management Software: Dedicated software solutions provide comprehensive features for managing inventory, including tracking stock levels, generating purchase orders, and analyzing sales data. These platforms streamline inventory control processes and offer valuable insights to optimize stock management.

Beyond tracking inventory, it’s essential to establish control measures to prevent stock losses, damages, and discrepancies.

- Regular stock audits: Periodic physical counts of inventory ensure that recorded data aligns with actual stock levels. This helps identify any discrepancies and implement corrective actions to prevent further losses.

- Proper storage and handling: Implementing standardized storage practices and handling procedures minimizes the risk of product damage or deterioration. This includes appropriate storage facilities, temperature control, and safe handling techniques.

- Inventory turnover rate analysis: Tracking the rate at which inventory is sold helps identify slow-moving or obsolete items. By analyzing turnover rates, you can adjust purchasing strategies to reduce dead stock and improve inventory efficiency.

By implementing a robust inventory tracking and control system, you gain a comprehensive understanding of your stock levels, identify potential issues, and make data-driven decisions to optimize inventory management. This ensures that your ecommerce business runs efficiently, minimizes losses, and maximizes profitability.

Optimizing Inventory Levels for Peak Efficiency

Maintaining the optimal inventory levels is a crucial aspect of running an efficient eCommerce business. You want to have enough stock to meet customer demands, but at the same time, you don’t want to tie up too much capital in inventory that might not sell quickly. This balance is where the magic happens. Finding the sweet spot between having too much and too little inventory will save you from facing inventory-related problems like stockouts, overstocking, and unnecessary storage costs.

To achieve this balance, consider adopting these strategies:

- Accurate Forecasting: The starting point for optimizing inventory levels is having a clear picture of future demand. Utilize historical sales data and seasonal trends to forecast anticipated demand accurately. Employ sophisticated forecasting tools for better insights.

- Safety Stock: Never underestimate the power of a safety stock. This buffer helps you avoid stockouts when demand spikes or unexpected delays occur. Calculate the optimal safety stock based on factors like lead time, demand variability, and desired service level.

- Inventory Turnover Rate: A higher inventory turnover rate is often a sign of healthy inventory management. It signifies that you’re selling your inventory quickly and efficiently. Regularly monitor this rate and adjust your ordering strategies to maintain a healthy turnover rate.

- ABC Analysis: Classify your inventory items based on their value and sales velocity. Focus on optimizing inventory levels for your ‘A’ items, which contribute significantly to your revenue, while having a less strict approach towards your ‘C’ items.

- Just-In-Time (JIT): Consider adopting a JIT inventory system to reduce your storage costs and waste. This system involves receiving inventory only when it’s needed, minimizing holding costs and the risk of obsolescence.

By implementing these strategies, you can gain a better understanding of your inventory needs, optimize stock levels, and ultimately achieve peak efficiency in your eCommerce operations.

Forecasting Demand and Adjusting Inventory Accordingly

Accurate demand forecasting is crucial for successful ecommerce inventory management. Predicting future sales allows you to optimize stock levels, reduce waste, and avoid lost sales.

Several techniques can help you forecast demand, including:

- Historical data analysis: Analyzing past sales data can reveal trends and patterns, providing a solid base for future predictions.

- Seasonality and trends: Consider seasonal variations, holidays, and market trends when making forecasts. For example, expect higher demand during the holiday season.

- Market research: Monitor competitor activity, industry trends, and consumer demand in your target market to refine your forecasts.

- Customer feedback and reviews: Analyze customer feedback and product reviews to identify popular items, potential upcoming trends, and any emerging customer preferences.

Once you have a demand forecast, you can adjust your inventory levels accordingly. This involves:

- Balancing supply and demand: Aim for a balance between meeting customer demand and minimizing excess inventory.

- Setting reorder points: Define specific inventory levels that trigger restocking orders. This helps prevent stockouts while avoiding overstocking.

- Utilizing safety stock: Maintain a reserve inventory to handle unexpected surges in demand or supply chain disruptions.

- Adopting flexible strategies: Be prepared to adjust your inventory levels based on real-time sales data and market changes.

By accurately forecasting demand and adjusting inventory levels accordingly, you can optimize your stock management, reduce waste, and ensure customer satisfaction, ultimately boosting your profitability.

Managing Deadstock and Avoiding Excess Inventory

Deadstock and excess inventory are two of the biggest nightmares for ecommerce businesses. They eat away at your profits and take up valuable storage space. But with some smart strategies, you can effectively manage deadstock and avoid accumulating too much inventory in the first place.

Identify and Analyze Deadstock: The first step is to identify your deadstock. This involves analyzing your inventory data to see which products are selling slowly or not at all. You can use various metrics like sales velocity, inventory turnover rate, and age of inventory to pinpoint deadstock. Once you have a clear picture of your deadstock, you can start taking action.

Strategies for Deadstock Management:

- Discount and Clearance Sales: Offer significant discounts or create clearance sections to get rid of deadstock quickly. This can be a good way to recoup some of your investment.

- Bundle Products: Combine deadstock items with popular products to create attractive bundles that can entice customers.

- Donate or Sell to Liquidators: If you can’t sell your deadstock, consider donating it to charity or selling it to a liquidator at a lower price.

- Repurpose or Upcycle: Explore the possibility of repurposing or upcycling deadstock items into something new and saleable.

Preventing Excess Inventory:

- Accurate Forecasting: Invest in a robust forecasting system that accurately predicts demand based on historical sales data, market trends, and seasonal variations.

- Demand Planning: Implement a demand planning process that takes into account factors like lead times, promotional campaigns, and potential disruptions to the supply chain.

- Agile Inventory Management: Opt for an agile inventory management approach that allows you to adjust inventory levels quickly based on changing demand patterns.

- Strategic Sourcing: Develop strong relationships with suppliers and negotiate flexible terms that allow you to adjust orders based on actual demand.

- Regular Inventory Audits: Conduct regular inventory audits to ensure that your stock levels are accurate and identify potential inventory problems early on.

By proactively managing deadstock and taking steps to avoid excess inventory, you can optimize your inventory levels, free up valuable cash flow, and boost your profitability.

Streamlining Your Supply Chain for Optimal Inventory Flow

A streamlined supply chain is crucial for any e-commerce business looking to optimize inventory flow and boost profitability. By eliminating inefficiencies and streamlining processes, you can ensure a smooth and consistent flow of products from supplier to customer, minimizing stockouts and maximizing customer satisfaction.

Here are some key strategies for streamlining your supply chain:

- Establish Clear Communication: Open and consistent communication channels between suppliers, manufacturers, and internal departments are essential. This includes sharing accurate demand forecasts, order updates, and inventory levels.

- Optimize Inventory Management: Implement a robust inventory management system that allows you to track inventory levels in real-time, predict demand accurately, and optimize stock levels. This includes using tools like demand forecasting algorithms and inventory turnover analysis.

- Centralize Operations: Centralizing your warehousing and fulfillment operations can lead to greater efficiency and cost savings. This allows for streamlined order processing, improved inventory visibility, and reduced shipping times.

- Leverage Technology: Utilize technology to automate tasks and processes within your supply chain, such as order management systems, warehouse management software, and supply chain planning tools. Automation can significantly reduce manual errors and improve overall efficiency.

- Optimize Shipping and Transportation: Negotiate favorable shipping rates with carriers, explore alternative transportation options, and implement efficient route planning to minimize delivery times and costs.

- Build Strong Relationships: Foster strong partnerships with suppliers and logistics providers to ensure a reliable and consistent flow of goods. This includes building trust, open communication, and a shared commitment to success.

By implementing these strategies, you can create a streamlined supply chain that facilitates optimal inventory flow, improves customer satisfaction, and ultimately drives profitability for your e-commerce business.

Leveraging Data Analytics to Improve Inventory Decisions

In the fast-paced world of e-commerce, efficient inventory management is paramount to success. Data analytics plays a crucial role in achieving this, providing valuable insights that can optimize stock levels, reduce waste, and ultimately, boost profitability.

By analyzing historical sales data, you can identify trends, seasonality, and customer preferences. This data can then be used to forecast demand, allowing you to proactively adjust inventory levels to meet anticipated needs. Real-time tracking of inventory allows for immediate adjustments based on changes in demand, ensuring you have the right products available at the right time.

Data analytics can also help you make smarter decisions regarding product assortment and pricing. By analyzing customer purchase patterns and competitor offerings, you can gain valuable insights into what products are in demand and how to optimize pricing strategies for maximum profitability.

Furthermore, analyzing shipping and fulfillment data can highlight areas for improvement in your supply chain. Identifying bottlenecks and inefficiencies allows you to optimize logistics and reduce costs associated with inventory storage and transportation.

Leveraging data analytics to inform your inventory decisions is no longer an option, but a necessity for e-commerce success. By harnessing the power of data, you can streamline operations, minimize waste, and maximize your profits in the competitive online marketplace.

Key Performance Indicators (KPIs) for Inventory Management

Monitoring your inventory management performance is crucial for maximizing profits and ensuring customer satisfaction. Key Performance Indicators (KPIs) provide valuable insights into your inventory health and efficiency. Here are some essential KPIs to track:

Inventory Turnover Rate: Measures how quickly your inventory is sold. A higher turnover rate indicates efficient inventory management and reduced holding costs.

Days Sales of Inventory (DSI): Represents the average number of days it takes to sell your inventory. Lower DSI signifies faster inventory turnover and better cash flow.

Inventory Accuracy: Reflects the accuracy of your inventory records. Accurate records are essential for efficient order fulfillment and preventing stockouts.

Stockout Rate: Measures the percentage of orders that cannot be fulfilled due to inventory shortages. Reducing stockout rates improves customer satisfaction and sales.

Order Fill Rate: Indicates the percentage of orders that are filled completely and on time. A high fill rate demonstrates efficient inventory management and strong customer service.

Average Lead Time: Represents the average time it takes to receive inventory from suppliers. Reducing lead times optimizes your supply chain and minimizes stockouts.

Holding Costs: Represents the cost associated with storing your inventory. Optimizing inventory levels can significantly reduce holding costs.

By closely monitoring these KPIs, you can gain valuable insights into your inventory management processes and identify areas for improvement. This data-driven approach allows you to optimize your inventory, reduce costs, and maximize your profitability.

Benefits of Effective Ecommerce Inventory Management

In the fast-paced world of ecommerce, having an effective inventory management system is crucial for success. It goes beyond simply tracking stock levels; it encompasses a holistic approach to optimizing your inventory processes for maximum efficiency and profitability. Here are some of the key benefits of implementing a robust ecommerce inventory management strategy:

Increased Sales and Revenue: Effective inventory management ensures that you have the right products available at the right time, preventing stockouts and lost sales. By minimizing out-of-stock situations, you satisfy customer demand, encourage repeat purchases, and ultimately drive higher revenue.

Improved Customer Satisfaction: Customers are more likely to be satisfied when they receive their orders promptly and accurately. An efficient inventory system ensures timely fulfillment, reducing shipping delays and minimizing returns. This leads to happier customers and a stronger brand reputation.

Reduced Costs: By optimizing inventory levels and minimizing waste, you can reduce storage costs, minimize write-offs due to expired or damaged goods, and streamline your supply chain. This translates into substantial cost savings that can be reinvested in other areas of your business.

Enhanced Data-Driven Decision Making: A well-structured inventory management system provides you with real-time data on stock levels, sales trends, and customer behavior. This valuable information empowers you to make informed decisions regarding product sourcing, pricing, and promotions, leading to better inventory forecasting and allocation.

Stronger Cash Flow: By managing your inventory effectively, you can optimize your working capital. Efficient inventory management minimizes the risk of holding excess stock, leading to improved cash flow and financial stability.

In conclusion, implementing a robust ecommerce inventory management strategy is essential for achieving success in the competitive online marketplace. By optimizing inventory processes, you can boost sales, improve customer satisfaction, reduce costs, and enhance your business’s overall profitability.

Common Mistakes to Avoid in Ecommerce Inventory Management

Managing inventory effectively is crucial for any e-commerce business. A well-managed inventory ensures customer satisfaction by minimizing stockouts and maximizing order fulfillment rates. However, many businesses fall into common traps that hinder their success. Here are some crucial mistakes to avoid when managing your e-commerce inventory:

1. Lack of Accurate Inventory Tracking: An accurate inventory count is the cornerstone of effective inventory management. Failing to track inventory levels precisely can lead to inaccurate reporting, missed sales opportunities, and unnecessary stockpiling. Employ a robust inventory management system that provides real-time visibility into your stock levels.

2. Inadequate Forecasting: Predicting future demand is critical for avoiding stockouts and overstocking. Neglecting to forecast demand accurately can result in lost sales due to product unavailability or excessive storage costs tied up in unsold inventory. Utilize data analysis tools and historical sales trends to improve your forecasting accuracy.

3. Ignoring Inventory Turnover Rate: The inventory turnover rate measures how quickly your inventory is sold. A low turnover rate indicates slow-moving products, leading to wasted storage space and potential obsolescence. Regularly analyze your inventory turnover rate to identify slow-selling items and adjust your ordering strategies accordingly.

4. Failing to Optimize Storage Space: Inefficient storage practices can lead to wasted space and increased storage costs. Implement efficient storage strategies, such as vertical racking and optimized warehouse layout, to maximize your warehouse’s capacity and reduce operational costs.

5. Lack of Supplier Relationship Management: Strong relationships with suppliers are vital for a reliable inventory supply. Neglecting to build and maintain these relationships can lead to supply chain disruptions and product shortages. Develop a strategic approach to supplier management, including regular communication and performance evaluations.

6. Overlooking Inventory Audits: Periodic inventory audits are essential for ensuring accurate inventory records and identifying discrepancies. Failing to conduct regular audits can lead to stock inaccuracies, which can negatively impact sales, profitability, and customer satisfaction.

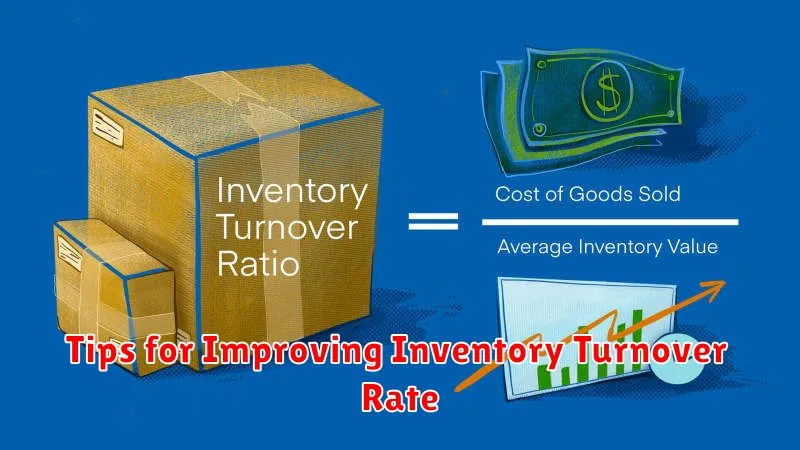

Tips for Improving Inventory Turnover Rate

A high inventory turnover rate is a crucial indicator of efficient ecommerce inventory management. It signifies that your products are moving quickly, leading to higher profits and less risk of stockouts. Here are some tips to help you improve your inventory turnover rate:

1. Accurate Demand Forecasting: Predicting future demand with accuracy is essential. Leverage historical sales data, market trends, and seasonal patterns to forecast demand effectively. This helps avoid overstocking and understocking.

2. Optimize Inventory Levels: Balancing inventory levels is key. Implement the ABC analysis to prioritize fast-moving items and minimize inventory on slow-moving ones. Regularly review inventory levels and adjust them based on demand fluctuations.

3. Reduce Lead Times: Minimize the time it takes to receive new stock. Negotiate better terms with suppliers, explore closer fulfillment centers, or implement just-in-time inventory practices. Shorter lead times mean faster replenishment and reduced inventory holding costs.

4. Implement Efficient Ordering Systems: Automate your ordering process to minimize human error and expedite stock replenishment. Use inventory management software that automates reordering points and tracks inventory levels in real-time.

5. Optimize Pricing Strategies: Strategic pricing can influence product demand. Adjust prices to incentivize sales, clear out slow-moving stock, and optimize inventory turnover.

6. Analyze and Improve: Regularly analyze your inventory turnover rate and identify areas for improvement. Use data to track your progress and adjust your strategies accordingly. Monitor key metrics such as the number of days of inventory on hand and inventory turnover period.

Integrating Inventory Management with Other Business Operations

Inventory management is a crucial aspect of any ecommerce business, but it’s not a standalone function. For true efficiency, inventory needs to be seamlessly integrated with other essential business operations. This interconnected approach can streamline workflows, enhance accuracy, and ultimately, maximize profits.

Here are some key areas where integrating inventory management is essential:

- Order Management: Real-time inventory updates ensure orders are fulfilled accurately and promptly. Automatic order allocation based on available stock prevents overselling and delays.

- Customer Service: Integrating inventory data with customer service systems allows representatives to provide accurate information about product availability, shipping times, and potential backorders, leading to improved customer satisfaction.

- Marketing and Sales: Integrating inventory with marketing and sales platforms enables targeted campaigns based on product availability and demand. This can help drive conversions and avoid losing potential customers due to out-of-stock items.

- Finance: Integration with financial systems provides a clear view of inventory costs, purchase orders, and sales revenue, facilitating accurate financial reporting and forecasting.

- Analytics and Reporting: Integrating inventory data with analytics tools allows businesses to track key metrics like inventory turnover, stock levels, and fulfillment rates, providing valuable insights for optimization and decision-making.

By integrating inventory management with these other crucial business functions, you can create a robust and streamlined system that minimizes errors, maximizes efficiency, and ultimately drives your ecommerce business forward.

Future Trends in Ecommerce Inventory Management

Ecommerce inventory management is constantly evolving, and businesses need to stay ahead of the curve to optimize their operations and maximize profits. Here are some key future trends in ecommerce inventory management that businesses should consider:

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are revolutionizing inventory management by automating tasks, predicting demand, and optimizing stock levels. AI-powered systems can analyze historical data, real-time trends, and customer behavior to forecast demand accurately. This helps businesses avoid stockouts and overstocking, ensuring they have the right products in the right quantities at the right time.

Real-Time Inventory Visibility: Real-time visibility into inventory levels across all channels is crucial for efficient management. Businesses need systems that provide accurate and up-to-date data on inventory availability, location, and movement. This enables them to make informed decisions about ordering, shipping, and fulfillment, minimizing delays and improving customer satisfaction.

Predictive Analytics: Predictive analytics leverages data to anticipate future demand patterns, helping businesses plan for seasonal fluctuations, promotions, and other factors that can impact inventory requirements. By analyzing historical data and external factors, businesses can proactively adjust inventory levels, reduce waste, and optimize stock allocation.

Cloud-Based Inventory Management Solutions: Cloud-based solutions offer flexibility, scalability, and cost-effectiveness. Businesses can access their inventory data and manage their operations from anywhere with an internet connection. Cloud-based platforms also provide real-time updates, collaboration tools, and integrations with other systems, simplifying inventory management and streamlining workflows.

Omnichannel Inventory Management: As the lines between online and offline channels blur, businesses need to manage inventory across all touchpoints. Omnichannel inventory management ensures a unified view of inventory across different channels, allowing for seamless fulfillment and customer experience.

Sustainable Inventory Practices: Environmental concerns are increasingly important for businesses. Sustainable inventory practices, such as reducing waste, optimizing transportation, and using eco-friendly packaging, can help businesses minimize their environmental impact while enhancing their brand image.

By embracing these future trends in ecommerce inventory management, businesses can optimize their operations, enhance customer satisfaction, and achieve sustainable growth.